As the core equipment of power production, the safe operation of power plant generators is crucial. However, during the operation of the generator, hydrogen leakage is a common problem that not only causes damage to the equipment, but may also lead to fire or explosion accidents. In order to improve the safety performance of the generator and ensure personnel safety, the power plant has adopted the NA1000D hydrogen leakage detection sensor for real-time monitoring of the hydrogen concentration in the generator.

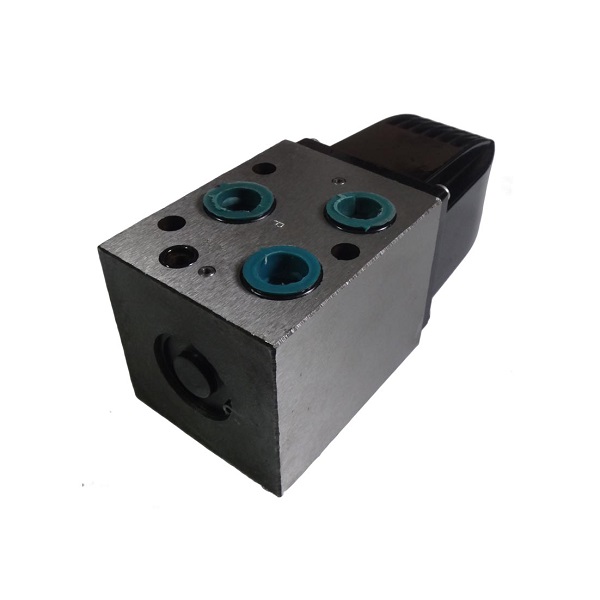

The NA1000D hydrogen detection probe is a high-performance and high-precision two wire transmitter with a built-in microcontroller that can digitally process the measured gas. This series of probes has the following features:

- 1. Digital processing: Sensors convert hydrogen concentration signals into electrical signals, achieving real-time monitoring and long-distance transmission, improving the accuracy and reliability of monitoring data.

- 4-20mA analog current output: The analog current signal output by the probe is easy to connect with control systems, alarm systems, and other equipment, achieving linkage control and alarm prompts.

- 3. High precision and good linearity: The probe has high measurement accuracy and good linearity, which can meet the high requirements of power plants for hydrogen concentration monitoring.

- 4. Convenient calibration and intelligence: The probe supports convenient and fast calibration operations, and through intelligent technology, automatically adjusts the measurement range and sensitivity to ensure long-term stable operation.

- 5. Sturdy structure: The probe adopts a sturdy structural design, which can adapt to harsh environments in power plants, such as high temperature, high humidity, corrosion, etc.

The application of NA1000D hydrogen detection sensors on power plant generators has the following advantages:

- 1. Real time monitoring: The probe can monitor the hydrogen concentration of the generator in real time, ensuring that the generator operates within a safe range.

- 2. Early warning: When the hydrogen concentration exceeds the preset alarm value, the probe will immediately issue an alarm signal to remind workers to take measures to prevent accidents from occurring.

- 3. Linkage control: The analog current signal output by the probe can be connected to the generator control system to achieve linkage control and reduce the risk of hydrogen leakage.

- 4. Improve safety: Through real-time monitoring and early warning, effectively reduce the occurrence of hydrogen leakage accidents in power plant generators, ensure personnel safety and equipment integrity.

- 5. Easy to maintain: The probe adopts a modular design, which is easy to install, maintain, and replace, reducing operation and maintenance costs.

In summary, the application of NA1000D series sensors in power plant generators helps to improve the safety performance of generators, ensure personnel safety, reduce accident risks, and provide strong guarantees for the stable operation of power plants.

Yoyik can offer many spare parts for power plants as below:

Photoelectric converter EMC-02

ALARM HORN; BC-110

LVDT Range 100mm

Eddy Current Sensor PR6423/002-041

DEH module K-FC01-B.0.0

Sensor DF312580-90-04-01

Axis vibration detection probe TM0180-A05-B05–C03-D10

inductive linear transducer TDZ-1-50

Pressure Switch ST307-55-B

Speed sensor CS-1G-G-060-02-00

Electric heating rod ZJ-18

Differential pressure transmitter CMS-035

Local operation box HSDS-40/LC

Cable Seal SS68-SEAL

lvdt in control system HL-6-50-15

Post time: Mar-15-2024