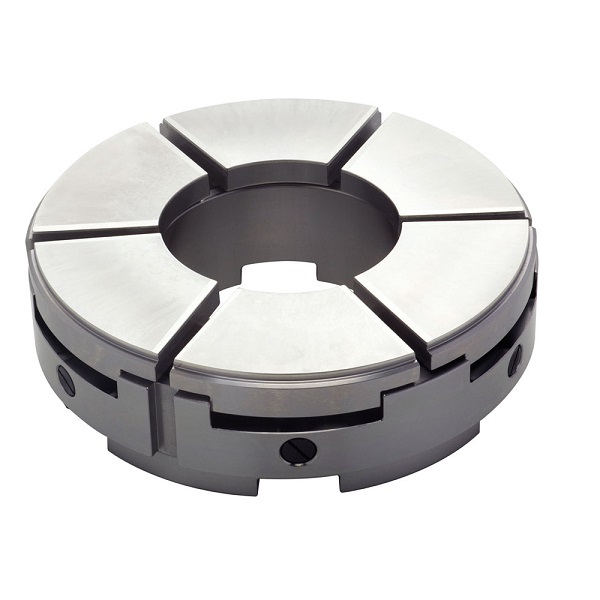

Bearing end cap DTSD30UZ004, as a crucial mechanical component, are the main external components of bearing seats and are widely used in various mechanical equipment. Its main working surface is the outer circular surface of the left and right end faces as well as the left end face, which has important functions such as axial positioning of the bearing outer ring, dust prevention and sealing, as well as transmitting torque and buffering shock absorption.

Firstly, the bearing end cap DTSD30UZ004 plays a crucial role in the axial positioning of the bearing outer ring. During the operation of mechanical equipment, the outer ring of the bearing needs to maintain a stable axial position to ensure the normal operation of the bearing. The bearing end cap achieves axial positioning of the outer ring by closely fitting with it, thereby ensuring the stability and reliability of the bearing.

Secondly, the bearing end cap DTSD30UZ004 also plays an important role in dust prevention and sealing. During the use of mechanical equipment, the lubricating grease inside the bearings needs to be kept clean to prevent dust and impurities from entering, in order to ensure the normal operation of the bearings. The bearing end cap itself has a certain dust-proof and sealing effect, and is often used in conjunction with sealing components to achieve better sealing effect. In this way, the working environment inside the bearing is effectively protected, extending the service life of the bearing.

In addition, the bearing end cap DTSD30UZ004 is also located between the lathe motor and the spindle box, mainly for transmitting torque and buffering vibration absorption. In mechanical equipment such as lathes, the rotation of the electric motor needs to be transmitted to the spindle box to achieve the operation of the machine tool. As an important component connecting the electric motor and the main spindle box, the bearing end cap can effectively transmit torque and play a buffering and shock-absorbing role, making the rotation of the main spindle box stable. In this way, the machining accuracy and stability of the machine tool are guaranteed, and the machining efficiency and quality are improved.

The manufacturing and design of bearing end cap DTSD30UZ004 is also very important. Firstly, it is necessary to select suitable materials such as cast iron, steel, etc. to ensure the strength and wear resistance of the bearing end cover. Secondly, in the design process, it is necessary to consider the fitting accuracy of the bearing end cover with other parts, as well as its installation and adjustment in mechanical equipment. In addition, the surface treatment of the bearing end cover is also crucial, such as oxidation, galvanizing, etc., to improve its rust and corrosion resistance performance.

In summary, as an important mechanical component, the bearing end cap DTSD30UZ004 has important functions such as axial positioning of the bearing outer ring, dust prevention and sealing, as well as transmitting torque and buffering shock absorption. Its manufacturing and design are also crucial, requiring the selection of appropriate materials, ensuring fitting accuracy, and surface treatment. The application of bearing end caps not only improves the performance and stability of mechanical equipment, but also extends the service life of bearings, making important contributions to the development of the mechanical processing industry.

Post time: Jan-22-2024