Float ball valve is a commonly used valve for hydraulic fluid control. Its principle is to control the opening and closing of the valve through the buoyancy of the float. When the liquid level rises or falls, the floating ball rises or falls with the liquid level, thereby changing the opening area of the valve, changing the flow rate, and controlling the liquid level.

In steam turbine generators, bearings are key components that support the rotor. The supply and discharge of bearing lubricating oil must maintain an appropriate flow rate and liquid level to ensure the normal operation and lifespan of the bearings. Floating ball valve is an essential valve for controlling the sealing oil of steam turbine generator, mainly used in float oil tank and vacuum oil tank, for liquid level control and flow control of the oil tank, ensuring the normal operation and lubrication of generator bearings.

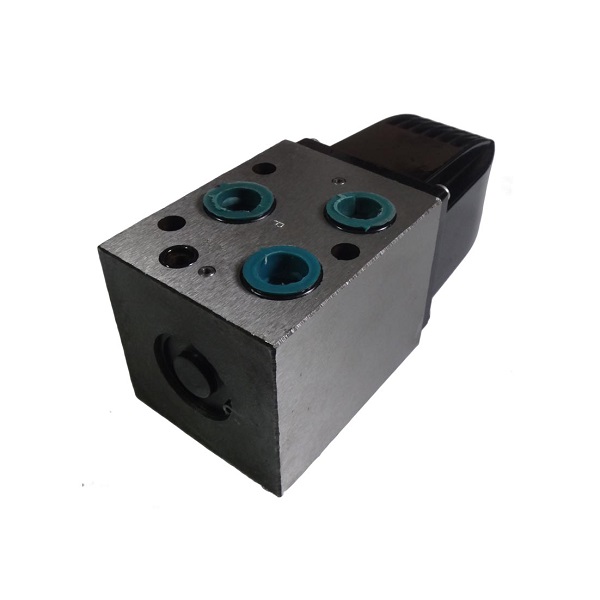

The commonly used float ball valves in power plants supplied by YOYIK are DN40 type and DN80 type. Among them, the DN80 floating ball valve has simple structure, reliable use, convenient operation, and easy installation.

The float ball valve DN80 consists of a valve body, a valve cover, a float ball, and a lever. It can achieve automatic control and adjustment of the flow and level of generator sealing oil. When the level of sealing oil decreases, the float valve will automatically open the oil inlet to increase the supply of sealing oil; When the liquid level rises, the float valve will automatically close the oil inlet to prevent excessive oil from entering the bearing, causing waste and unnecessary load.

As an important valve for maintaining the normal operation of generator bearings, the DN80 float ball valve requires regular inspection and maintenance to ensure its normal operation and extend the service life. Here are some common methods:

1. Regular cleaning: Regular cleaning of float ball valves can remove debris and dirt from the pipeline, maintain the smoothness and cleanliness of the valve, and reduce the occurrence of valve jamming and faults.

2. Check the float: Regularly check the surface and interior of the float for damage or corrosion, and if so, replace it in a timely manner.

3. Lubricating the valve: Regularly apply lubricating oil or grease to the valve to ensure its flexibility and stability.

4. Check the sealing parts: Regularly check the sealing parts of the valve for aging or wear, and replace them in a timely manner if necessary.

5. Check the lever: Regularly check whether the connection of the lever is loose or detached, and if necessary, repair or replace it in a timely manner.

6. Prevention of excessive use: Avoid excessive use of float valves to avoid valve wear and failure.

Post time: Apr-18-2023