Hydrogen cooled generators require high-quality sealant to seal hydrogen because hydrogen is a very light and small molecule that can penetrate through the gaps and pores of many traditional sealing materials and devices, leading to leakage. The high-quality hydrogen sealing sealant has the characteristics of high strength, high toughness, and low gas permeability, which can better seal hydrogen and ensure the safe operation of the generator.

Sealing Principle of Generator Hydrogen Sealant

The sealing principle of generator hydrogen sealant D20-75 is mainly to fill the pores and micro cracks on the surface of the sealing element to achieve a certain sealing effect. Sealant can fill irregularly shaped pores and micro cracks on the surface of the generator end cover, making the surface smoother and increasing the surface hardness and wear resistance to a certain extent, thereby improving the sealing performance of the sealant. In addition, the high viscosity of the sealant can also prevent hydrogen gas from penetrating into the interior of the seal, protecting the material of the seal from corrosion by hydrogen gas. It can be said that the sealing effect of the sealant is directly related to the operational safety and reliability of the hydrogen cooled steam turbine generator.

Quality Standard of Hydrogen Sealing Sealant

As a manufacturer of hydrogen sealing sealant D20-75 for generators, Yoyik recommends several quality standards that you should pay attention to when selecting hydrogen sealing sealant.

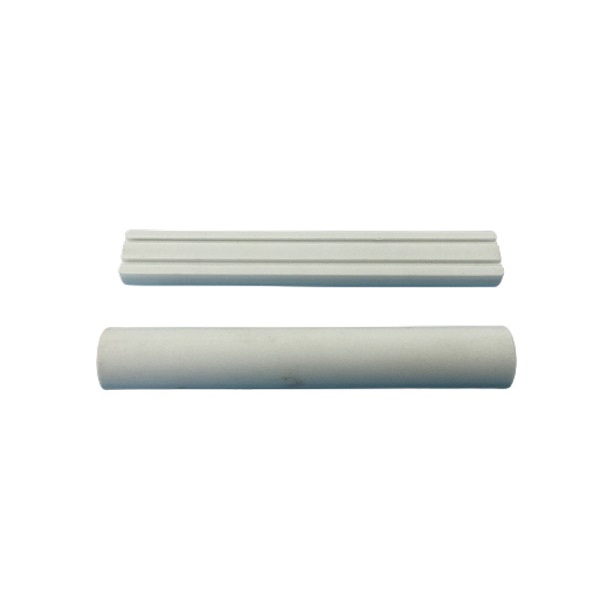

1. Physical properties: The appearance of the hydrogen sealing sealant should be uniform in color, free of particles, bubbles, and free from solidification, agglomeration, and other phenomena. The specific gravity, viscosity, curing time, and other physical properties of the sealant should comply with relevant standards or requirements.

2. Chemical properties: The chemical properties of the sealant should be stable and will not react due to contact with other materials, such as corrosion, discoloration, and other phenomena.

3. Temperature resistance: Hydrogen sealing sealant should have good temperature resistance and can maintain stable performance for a long time at high or low temperatures.

4. Adhesion: The sealant should have good adhesion and can firmly adhere to the surface of various components of the generator.

5. Aging resistance: the sealant shall have good aging resistance, be able to maintain stable performance for a long time, and will not decline in sealing performance due to the passage of time.

However, there are various types of hydrogen sealing sealants in the market, including some low-quality products. Yoyik Special Reminder: Poor quality hydrogen sealing sealant may cause the following hazards:

1. Poor sealing performance: The sealing performance of low-quality hydrogen sealing sealant may be unstable and prone to leakage, leading to hydrogen leakage and increasing safety hazards.

2. Poor heat resistance: The working environment temperature of the hydrogen cooling system is high, and the heat resistance performance of low-quality hydrogen sealing sealant is poor, which may lead to sealant failure and increase maintenance costs.

3. Short lifespan: Poor quality hydrogen sealing sealants may have a shorter lifespan and require more frequent replacement, increasing maintenance costs and risks.

Post time: Apr-19-2023