Double sealing ring DTYD100TY004 usually refers to a sealing element composed of two or more sealing rings combined to form a whole, used to enhance the sealing effect. In mechanical design and industrial applications, double sealing rings can effectively prevent fluid or gas leakage, ensuring the integrity and performance of the system.

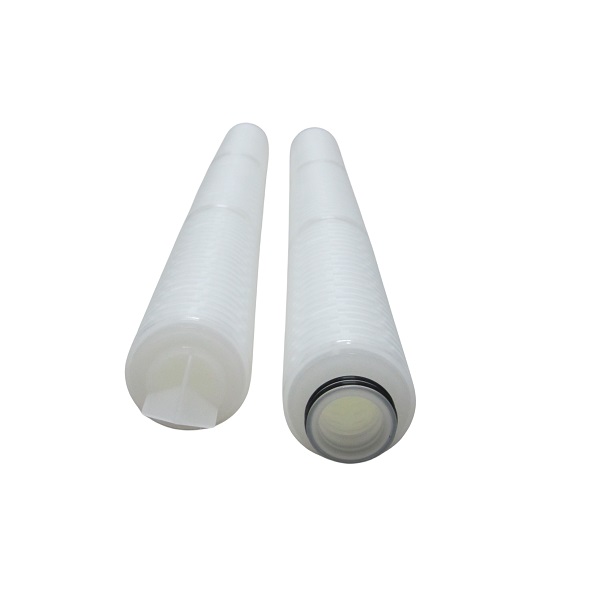

Structurally speaking, a dual sealing ring DTYD100TY004 may be designed with two identical sealing rings arranged side by side, or one sealing ring may have another auxiliary sealing structure integrated inside. This design can improve the reliability of sealing without increasing installation space.

The working principle of the double sealing ring DTYD100TY004 is mainly to use the elastic deformation of the sealing ring to achieve sealing effect. When the sealing ring is installed in the preset sealing chamber, under pressure, the sealing ring will deform and adhere to the sealing surface, thereby preventing fluid or gas from passing through the sealing interface. In dual design, the second sealing ring is usually used to compensate for the wear of the first sealing ring or provide a backup sealing effect, so that even if the first sealing ring is damaged, the second sealing ring can still maintain its sealing effect.

In different application scenarios, the material, shape, and size of the double sealing ring DTYD100TY004 may vary to adapt to different pressure, temperature, and medium requirements. For example, in car engines, dual seals may need to be resistant to high temperatures and oil stains; in water treatment systems, corrosion resistance may be required.

The characteristics of the dual seal ring DTYD100TY004 are mainly reflected in the following aspects:

1. Enhanced sealing performance: The dual sealing ring enhances its ability to prevent leakage through a dual sealing design. Even in high pressure or temperature environments, it can maintain good sealing performance.

2. Reliability: Due to the fact that dual seals typically contain two independent sealing elements, even if one seal fails, the other can still function, ensuring the reliability of the system.

3. Wear resistance: The material of the double sealing ring usually has good wear resistance, which can adapt to dynamic sealing environments and extend its service life.

4. Adaptability: The design of the dual sealing ring can adapt to various sizes and shapes of sealing chambers, with high installation flexibility.

Double sealing rings DTYD100TY004 are widely used in industries such as automobiles, machinery, petroleum, and chemicals, and are of great significance in ensuring the safe operation of equipment, improving production efficiency, and product quality.

Post time: Jan-31-2024