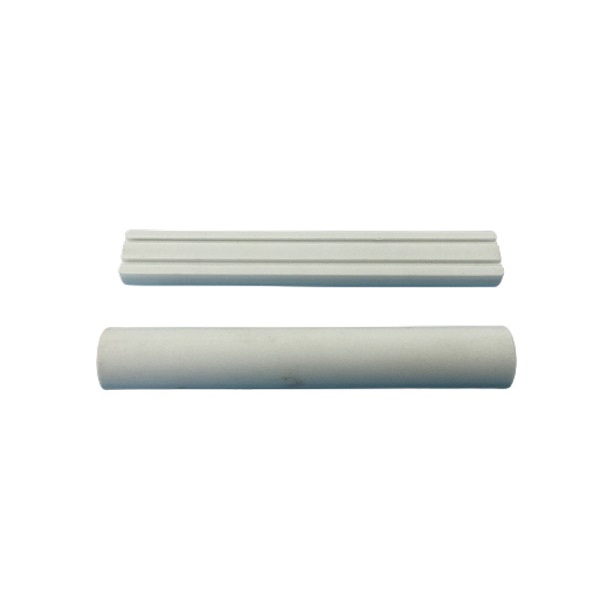

Cone end set screw, also known as cone screw or cone end screw, is a mechanical fastening component. Its characteristic is that the top of the thread is conical, which provides greater grip and torque, making the screw more reliable during tightening. Cone end set screws come in different specifications and materials, including stainless steel, alloy steel, etc., to meet different application requirements and environmental conditions. When selecting and using tapered screws, it is necessary to consider factors such as the size, material, load conditions, and expected service life of the fasteners.

Cone end fastening screws are widely used in various mechanical and electronic devices for fixing and connecting components. In large generator sets, cone end screws are also a commonly used fastener, but they need to withstand high torque and vibration. Therefore, generator specific screws need to have higher strength and durability.

In a generator set, the tapered end set screw may be used for the following purposes:

- 1. Fixation of generator components: The turbine and generator components of the generator set need to be accurately positioned and tightened to ensure stability and efficiency of operation. The tapered end set screw can provide sufficient grip to ensure that these components remain fixed in high-speed rotation and vibration environments.

- 2. Connection between bearings and flanges: In generator sets, the connection between bearings and flanges also requires the use of tapered end set screws to ensure sealing and tightness. These screws can withstand axial and radial loads between the bearings and flanges.

- 3. Connection between outlet and inlet pipelines: The inlet and outlet pipelines in the generator set also need to be connected using tapered end set screws. These screws can resist pressure and temperature changes in the pipeline while maintaining the sealing of the pipeline.

In order to meet the special requirements of large power generation units, fasteners such as tapered end set screws are usually made of high-strength materials, such as alloy steel 2Cr12WMoVNbB, 25Cr2Mo1VA, 40Cr2MoVA, 1Mn18Cr18N, etc., and may undergo heat treatment to improve their wear resistance and corrosion resistance. In addition, these screws may also be treated with special surface treatments such as galvanizing or coating to prevent corrosion and improve their service life.

Yoyik can offer many spare parts for power plants as below:

Steam turbine Hexagon socket head cap screw

Primary fan Adjusting ring DTPD30LG002

Thrust ring GB/T7813-1998

Generator insulating bush for bearing oil seal

Steam turbine Flange through-hole equal length stud

Generator Double headed bolt

Steam turbine generator sealing strip

Generator Copper braid for rotor grounding

Coal mill Rotary separator stationary blade 20MG50.11.15X.04.99

Steam turbine Spacer

Induced draft fan Sealing cooling fan DTYJ60UM001

Generator TZ-1 copper braided flat wire

Generator spring for steam end seal tile

Generator Sealing gasket

Booster pump O-ring DG600-240-07-01(10)

Booster pump Oil baffle ring FA1B56-A2-102761

Steam turbine Accuator shaft

Steam turbine HIP casing gasket

Steam turbine Thrust pads

Steam turbine Valve stem

Electric feedwater pump Nut seal sleeve (NDE) DG600-240IIM-03-05

Generator Bearing alloy WJ2B

Steam turbine Hexagon headed bolt

Contact us if your need the above spare parts, or want to find any item used in power plants.

Post time: Feb-19-2024