The ZS-04-A75 speed sensor can provide accurate speed measurement, is widely used in various industrial applications, such as speed monitoring of steam turbines, generators, compressors, and other rotating machinery. It plays an important role in maintaining the normal operation of equipment, preventing faults, and ensuring production safety.

When installing the speed sensor ZS-04-A75, it is indeed necessary to pay attention to the clearance between the detection gear. This gap will affect the output voltage of the sensor, as the smaller the gap, the faster the magnetic field changes, resulting in a greater potential change and an increase in output voltage. However, a small gap may cause contact between the gear and the sensor, leading to damage to the sensor or gear. Therefore, it is necessary to find an appropriate gap that can ensure sufficient signal strength without causing contact.

Usually, there is a recommended installation clearance range in the sensor manual, which can be referred to. During actual installation, it is generally recommended to use involute gears to detect tooth profile, which can ensure the correct position and clearance of the gears.

For the installation of the speed probe ZS-04-A75, the following factors need to be considered:

- 1. Environmental conditions: The installation location should avoid strong vibrations, high temperatures, high humidity, excessive dust, or other environmental factors that may affect the performance of the sensor.

- 2. Installation requirements: Determine the optimal installation position and clearance based on the actual operating conditions of the power plant and the technical specifications of the sensors.

- 3. Safe operation: When installing or maintaining sensors, ensure that the power is turned off and avoid live operation to prevent electric shock or damage to the sensor.

- 4. Wiring terminal: The wiring terminal should be tightly pressed to ensure stable connection and avoid signal loss or short circuit caused by poor contact.

- 5. Cable and Terminal: After wiring is completed, the contact between the cable and terminal should be checked to ensure that there is no short circuit or looseness.

- 6. Working power supply: Confirm that the working power supply of the sensor meets the requirements, and carry out appropriate environmental protection measures for the signal connection cable according to the on-site environment, such as moisture-proof and dust-proof.

There are different types of rotating speed sensor used for different steam turbine units. Check if it has the sensor you need, or contact us for more details.

Speed Converter DF6101-005-065-01-09-00-00

magnetic pickup sensor price CS-1-D-065-05-01

vibration pickup sensor SEC-143.35.19

SWITCH PROXIMITY DF6202DF6202005050040001000\VM600

Sensor Magnetic CS-1 L=65

Magnetic Spd Pickup Sensor Ht 330103-00-08-10-02-00

DEH speed sensor CS-1 D-065-05-01

Tachometer Transmitter CS-01

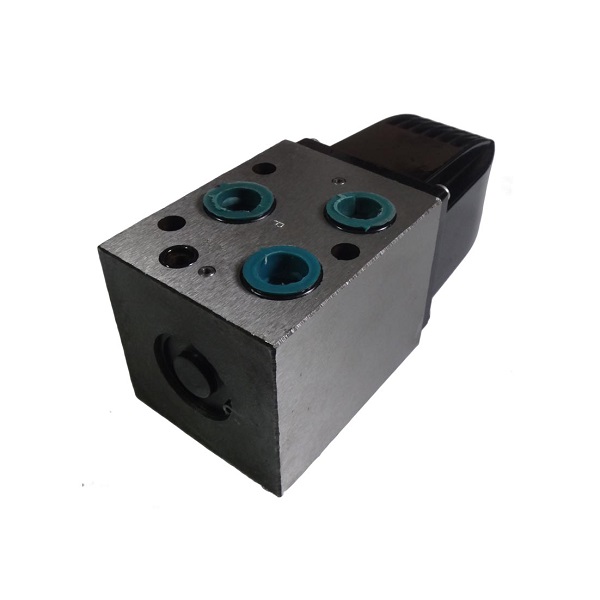

magnetic pickup amplifier ZS-04-75

rotational velocity sensor CS-1 G-090-02-01

pickup sensor CS-1 L=90

magnetic tachometer sensor CS-1(G-065-02-01)

SWITCH PROXIMITY CS-1 L100

Low Resistance Probe ZS-06

Rotating speed probe CS-1 G-100-03-01

Post time: Dec-28-2023