The solenoid valve seat 3D01A011 is one of the core components of the steam turbine AST control system. It is a multi-channel hydraulic control unit used to control the flow direction, pressure, and flow rate of hydraulic oil. Reducing leakage points during use is the key to ensuring system reliability. Here we introduce some methods to help reduce system leakage points and improve the overall performance and reliability of the system.

Firstly, it is crucial to choose high-quality valve seat 3D01A011. The use of rigorously tested high-quality hydraulic valve blocks can ensure excellent sealing performance and durability. It is made of high-quality alloy, which can ensure compliance with the system configuration.

Secondly, proper installation is also an important measure to reduce leakage points. When installing the solenoid valve seat 3D01A011, it is necessary to follow the manufacturer’s instructions to ensure that all interfaces and connection points are sealed in the correct way. Use appropriate seals, such as O-rings, washers, etc., to ensure no leakage.

Regular inspection and maintenance are also key to preventing leaks. During system operation, valve block 3D01A011 and the connection points of the system should be regularly checked to ensure that the seals are not worn or damaged. Once damaged seals are found, they should be replaced immediately to prevent leakage.

In addition, avoiding excessive pressure is also an important measure to reduce leaks. The working pressure of the system should not exceed the design pressure of the valve block and seal. If the pressure is too high, it may cause seal damage and leakage. Therefore, when designing the system, it is important to ensure that the working pressure is within a safe range.

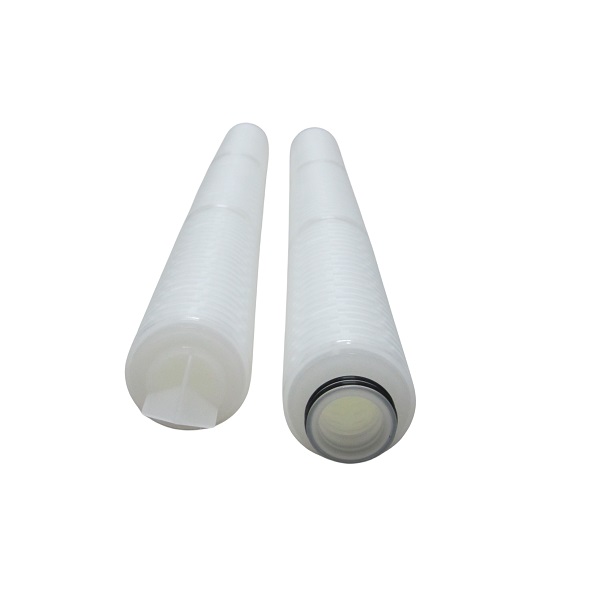

In addition, maintaining the cleanliness of EH oil is also an important measure to prevent leaks. Contaminants may damage seals and cause leaks. Therefore, measures should be taken to prevent pollutants from entering the system, such as using filters.

Finally, avoiding unnecessary modifications is also the key to reducing leaks. Unnecessary modifications may affect the sealing performance of the valve seat. Therefore, when designing and maintaining the system, unnecessary heat treatment or modification of the solenoid valve seat 3D01A011 should be avoided as much as possible.

Yoyik can offer many spare parts for power plants as below:

SERVO VALVE G772K620A

Isolation valve F3DG5S2-062A-220DC50-DFZK-V/B08

installation screen by switching piece JL1-2.5/2

Bladder NXQA-10/31.5

automatic gearbox types M01225.OBMCC1D1.5A

globe valve parts WJ15F1.6P

Electrohydraulic servo valve G761-3969B

solenoid valve coil 230v CCP115M

solenoid valve 3D01A005

Reduction gearbox M02225.OBGCC1D1.5A

AST solenoid valve C9206013

Electromagnetic valve 165.31.56.03.02

solenoid valve HQ16.14Z

EH pump PVH074R01AA10A250000001001AB010A

solenoid valve J-220VDC-DN6-D-20B/2A

Post time: Mar-22-2024